Database for equipment...

Database for equipment...

Hello Everyone,

A number of you have asked for a database of equipment. Since we are unsure of what equipment specs you would like added to BTP we will call upon you. Please post detailed equipment specs you would like to see added. Lets try to avoid filling this post up with non-equipment information.

Please try to be as "scientific" as possible with your data. Our goal is good data!

You guys Rock!

A number of you have asked for a database of equipment. Since we are unsure of what equipment specs you would like added to BTP we will call upon you. Please post detailed equipment specs you would like to see added. Lets try to avoid filling this post up with non-equipment information.

Please try to be as "scientific" as possible with your data. Our goal is good data!

You guys Rock!

Lathe

BeerTools.com Staff

BeerTools.com Staff

Lathe,

Hope this is not too general (although I know it is). Basically everything that we set up under vessels right now that has an impact on mash schedules.

1) Vessels: Mash Tun, Lauter Tun, Boil Kettle

2) Heatsource: Cajun cookers, Propane/Natural Gas burners, Electric for those with rims etc.

3) Equipment Loses for those that have herm/rim system. Not sure how those guys are dealing with losses to plumbing etc.

Later,

Jaw

PS. Thanks for finally answering. I think a database for this makes more sense that having template files. I'm sure we would all contribute to the database with commonly used equipment.

Hope this is not too general (although I know it is). Basically everything that we set up under vessels right now that has an impact on mash schedules.

1) Vessels: Mash Tun, Lauter Tun, Boil Kettle

2) Heatsource: Cajun cookers, Propane/Natural Gas burners, Electric for those with rims etc.

3) Equipment Loses for those that have herm/rim system. Not sure how those guys are dealing with losses to plumbing etc.

Later,

Jaw

PS. Thanks for finally answering. I think a database for this makes more sense that having template files. I'm sure we would all contribute to the database with commonly used equipment.

iMac 27", 3.4 GHz Intel Core i5, 8GB Ram, Mac OSX 10.12.6

iPhone 7+

iPad Pro 10.5

I like macs

iPhone 7+

iPad Pro 10.5

I like macs

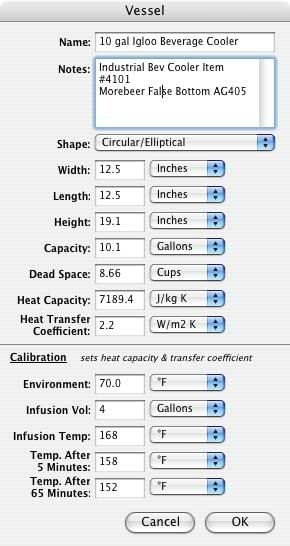

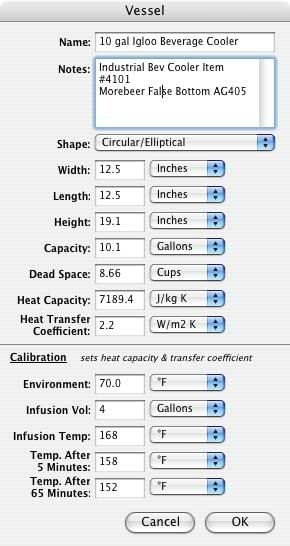

Is this what you had in mind??

Mash Tun

Name: Igloo Cool Roller

Capacity: 56 Qt.

Shape: Rectangular

Inside Dimensions:

Width: 11.5 in.

Length: 20.5 in.

Height: 13.25 in.

Calibration Steps (after near boiling water sitting then drained for 30 min.)

Environmental Temp: 60.0 F

Infusion Volume: 5.0 Gal

Infusion Temp: 159.0 F

Temp after 5 min.: 156.0 F

Temp after 60 min. : 151.0 F

Heat Capacity 2473.9 J/kgK

Heat Trans Coeff: 1.4 W/m2K

Mash Tun

Name: Igloo Cool Roller

Capacity: 56 Qt.

Shape: Rectangular

Inside Dimensions:

Width: 11.5 in.

Length: 20.5 in.

Height: 13.25 in.

Calibration Steps (after near boiling water sitting then drained for 30 min.)

Environmental Temp: 60.0 F

Infusion Volume: 5.0 Gal

Infusion Temp: 159.0 F

Temp after 5 min.: 156.0 F

Temp after 60 min. : 151.0 F

Heat Capacity 2473.9 J/kgK

Heat Trans Coeff: 1.4 W/m2K

Igloo Cooler, 10 gal

I was hoping this thread would fill up fast so that I could confirm my measurements, but since it isn't I guess I'll quit lurking. Speak up if you see anything that looks way off. The first is my 10 gallon Igloo "drinking water" cooler. It is fitted with a 12" stainless steel dome-shaped false bottom, and I use it as a mash tun. I think this is a very common configuration in homebrewing.

Shape: Circular

Width: 13 inches

Length: 13 inches

Height: 18 inches

Capacity: 10.3 gallons

Dead Space: 0.5 quarts

Heat Capacity: 3801.5 J/kg K

Heat Transfer Coefficient: 0.6 W/m2 K

---- Calibration----

Environment: 55 F

Infusion Vol: 4.0 gallons

Infusion Temp: 161 F

Temp after 5 min: 155 F

Temp after 65 min: 153 F

Shape: Circular

Width: 13 inches

Length: 13 inches

Height: 18 inches

Capacity: 10.3 gallons

Dead Space: 0.5 quarts

Heat Capacity: 3801.5 J/kg K

Heat Transfer Coefficient: 0.6 W/m2 K

---- Calibration----

Environment: 55 F

Infusion Vol: 4.0 gallons

Infusion Temp: 161 F

Temp after 5 min: 155 F

Temp after 65 min: 153 F

Sanke keg kettle

This is a standard converted Sanke keg with the top cut out for use as a 15.5 gallon brew kettle. Mine has a copper dip tube fitted with a bazooka screen.

Shape: Circular

Width: 15.5 inches

Length: 15.5 inches

Height: 19 inches

Capacity: 15.5 gallons

Dead Space: 1 quart

Heat Capacity: 7259.7 J/kg K

Heat Transfer Coefficient: 9.8 W/m2 K

---- Calibration----

Environment: 55 F

Infusion Vol: 4.0 gallons

Infusion Temp: 162 F

Temp after 5 min: 151 F

Temp after 65 min: 118 F

Shape: Circular

Width: 15.5 inches

Length: 15.5 inches

Height: 19 inches

Capacity: 15.5 gallons

Dead Space: 1 quart

Heat Capacity: 7259.7 J/kg K

Heat Transfer Coefficient: 9.8 W/m2 K

---- Calibration----

Environment: 55 F

Infusion Vol: 4.0 gallons

Infusion Temp: 162 F

Temp after 5 min: 151 F

Temp after 65 min: 118 F

Igloo Cube Cooler, 50 qt.

I use this Igloo Cube as a HLT, so I don't have a false bottom or anything in it (I've been listing the modifications, just in case any are significant enough to affect the temperature measurements, dead space, etc.). I'm a little suspicious of my heat transfer coefficient, because it seems like the water temperature dropped too much in 65 minutes, so I may run this test again later.

Shape: Rectangular

Width: 14.5 inches

Length: 14.5 inches

Height: 14.5 inches

Capacity: 13.2 gallons

Dead Space: 0 quart

Heat Capacity: 5509.4 J/kg K

Heat Transfer Coefficient: 3.1 W/m2 K

---- Calibration----

Environment: 55 F

Infusion Vol: 4.0 gallons

Infusion Temp: 180 F

Temp after 5 min: 170 F

Temp after 65 min: 156 F

Shape: Rectangular

Width: 14.5 inches

Length: 14.5 inches

Height: 14.5 inches

Capacity: 13.2 gallons

Dead Space: 0 quart

Heat Capacity: 5509.4 J/kg K

Heat Transfer Coefficient: 3.1 W/m2 K

---- Calibration----

Environment: 55 F

Infusion Vol: 4.0 gallons

Infusion Temp: 180 F

Temp after 5 min: 170 F

Temp after 65 min: 156 F

Brant,

Looks like you have the same coolers as I do. I will see if I can't get those numbers this weekend to confirm.

Oh and by database for equipment, I meant a database within the BTP program. Hope this happens.

Thanks,

jaw

Looks like you have the same coolers as I do. I will see if I can't get those numbers this weekend to confirm.

Oh and by database for equipment, I meant a database within the BTP program. Hope this happens.

Thanks,

jaw

iMac 27", 3.4 GHz Intel Core i5, 8GB Ram, Mac OSX 10.12.6

iPhone 7+

iPad Pro 10.5

I like macs

iPhone 7+

iPad Pro 10.5

I like macs

finally i get the time to calibrate one piece of equipment

UPDATE:

Heat Capacity = 5200.0 j/kg k

Heat Xfer = 0.44 w/m2 k

UPDATE:

Heat Capacity = 5200.0 j/kg k

Heat Xfer = 0.44 w/m2 k

Last edited by jawbox on Sun Jan 18, 2009 8:46 am, edited 1 time in total.

iMac 27", 3.4 GHz Intel Core i5, 8GB Ram, Mac OSX 10.12.6

iPhone 7+

iPad Pro 10.5

I like macs

iPhone 7+

iPad Pro 10.5

I like macs

Well, I forgot about the cheat that I later I admitted to here http://www.beertools.com/forum/viewtopic.php?t=2520 (about halfway down that message thread). Throw out my 65-minute number if you don't trust it -- but it fits my real-life mashes (and makes the BTP schedule work out much better for me!!!).

I also posted something on page 7 or 8 of the Bug Reports message about thoughts on deadspace, and whether a siphon is pulling up from the diptube, or if the flow rate is slow enough that nothing below the level of the drain hole will be pulled up and out. When I posted my deadspace measurement, it was from a full flow rate, so it pulled out more water. That's probably the wrong thing for me to have done, since I typically fly sparge slowly.

In fact, it looks like none of our measurements match each other! I've seriously been thinking about re-measuring my Heat Capacity (the 5-minute temperature test), though at this point, I think I might just monkey with the number until my strike temperatures are dead on. They are pretty close as is, just a little too high. Ironically, that means I'll be reducing the Heat Capacity of mine, taking it ever farther away from your number. I'm not really sure what's going on....

I also posted something on page 7 or 8 of the Bug Reports message about thoughts on deadspace, and whether a siphon is pulling up from the diptube, or if the flow rate is slow enough that nothing below the level of the drain hole will be pulled up and out. When I posted my deadspace measurement, it was from a full flow rate, so it pulled out more water. That's probably the wrong thing for me to have done, since I typically fly sparge slowly.

In fact, it looks like none of our measurements match each other! I've seriously been thinking about re-measuring my Heat Capacity (the 5-minute temperature test), though at this point, I think I might just monkey with the number until my strike temperatures are dead on. They are pretty close as is, just a little too high. Ironically, that means I'll be reducing the Heat Capacity of mine, taking it ever farther away from your number. I'm not really sure what's going on....

- billvelek

- Imperial Stout

- Posts: 801

- Joined: Fri Mar 05, 2004 9:44 am

- Location: Arkansas, USA

- Contact:

Possibly a new, unconsidered calibration issue

I've read the last few posts and have mulled this around in my head a bit. We have possible variables during calibration including possible fluctuation of room temp; I would think that room temp wouldn't ordinarily change too much, and I don't know how much of a difference inside the tun a 3 degree difference would make outside the tun, but probably only a small fraction of a degree. Other variables, such as grist and/or the tun possibly being a different temp than ambient, mean that one could possibly have three different temps -- all of them varying from what the ambient was during the calibration. The extra empty space in a tun (because grains are not present during calibration) might affect calibration, but probably not much if BTP is using proper formulas (thermal mass is thermal mass, and R factor is R factor [insulating quality]), regardless of the amount of heat added to test it. I don't know how crucial it is to worry about so many things, but the one thing I haven't seen mentioned yet is the effect of having the tun calibrated with the lid on and yet having the lid off for a time during certain steps. With the lid off, there are bound to be increased losses of heat. For instance, when I mash in, I spend time mixing the grist and water to try to be sure thickness is relatively uniform and that there are no dough balls, and then temperature checks take longer, too, because I will sample several spots in my mash which probably takes a good minute longer than the temperature check during calibration. If I do a two-step infusion, we have more time without the lid. Vorlauf takes a good bit of time with the lid off, PLUS heat loss to the pot that I use to drain and return the liquor to the tun. So I'm thinking that for the MOST accurate calibration, BTP ought to try to determine R factor (actually called heat transfer coefficient by BTP) with the lid on and also with the lid off, and then have the user indicate the lengths of time that the lid would be off. In the absence of that, is it adviseable to leave the lid off during a portion of the calibration. I mean, if I normally spend a minute 'doughing in' and another minute checking temp -- for a total of 2 minutes without the lid during mash in -- would it be advisable to leave the lid off for the first 2 minutes of the initail 5 minute calibration period. I don't think that would actually accomplishe the same thing but at least it provides some sort of simulation.

Anyone else have any thoughts along those lines?

Cheers.

Bill Velek

Anyone else have any thoughts along those lines?

Cheers.

Bill Velek

I left the lid off for the first 5 minutes, figuring that corresponded reasonably closely to my dough-in and heat stabilization time. The factor that I left out, I now realize, is that I stir for close to 5 minutes during dough-in, but didn't stir during the 5 minute stage of the calibration. Heat loss to the air will be greater with stirring than without.

BTP v2.0.* Windows XP

- billvelek

- Imperial Stout

- Posts: 801

- Joined: Fri Mar 05, 2004 9:44 am

- Location: Arkansas, USA

- Contact:

That's true, too.

Yes, I stir too, and you are correct that this will increase heat loss somewhat. And actually, I just guesstimated my dough-in time; I'm not sure I ever really took notice because I start my timer as soon as I dump the strike water, and then stir for a bit until I'm satified it is well blended, and then I check temp. I'm sure it takes me at least a couple of minutes, but it could well take longer. On the other hand, as soon as I'm satified with temp, I put the lid on until the next infusion, so it's as stable as it will get from that point, ... but I can see how this could affect the strike water temp, although probably not more than a couple of degrees. But I guess if we're going to the trouble of calibrating vessels, I guess we could bother trying to compensate for a couple of stray degrees, too.slothrob wrote:I left the lid off for the first 5 minutes, figuring that corresponded reasonably closely to my dough-in and heat stabilization time. The factor that I left out, I now realize, is that I stir for close to 5 minutes during dough-in, but didn't stir during the 5 minute stage of the calibration. Heat loss to the air will be greater with stirring than without.

I also want to comment that leaving the lid off during the first 5 minutes might actually be the worse time to do that. I say this because that is the time that BTP is computing thermal mass rather than heat loss to the environment -- which is what happens when you have the lid off. Are we straining for gnats here? Of course, I was the one who brought it up, but then again I'm pretty anal.

Cheers.

Bill Velek